Chassis-plate

966 chassisplate made of american aerospace quality aluminium 7075 T6. Precison CNC machined with chamfered edges to prevent touching when cornering, countersunk holes to seat the steel allen screws, shaped cooling pocket below the engine, positioning holes for the engine-mount screws, positioning holes for the steel pins to hold the alu rear end brackets, recessed area for the carbon fibre battery-plate, and a recessed area to fit the optional brass front plate for stiffness and weight or the carbon fibre insert for additional stiffness. Serpent laser-logo.

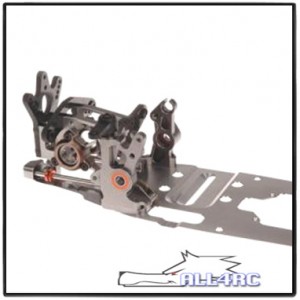

Brake

Lower mounted brake-assembly for lower LCG. Spring-loaded brake-plates slides on polished steel shafts. Ready-to-run brake plate/pads assembly with new friction brake material. The ball-raced hard anodized brake-cam push the 2 larger pins which are seated in the aluminium bracket, against the brakeplat, to create very smooth and even pressure to the plate.

2-speed shaft

CNC machined anodized aluminium 2-speed shaft brackets, offer perfect seating for the bearings. Lets and right side support the ball-raced rear anti-roll bar and 2-speed shaft. Left side also support the carbon fibre side bracket and so the the right one.

Main rear brackets

Anodized, cnc machined, aluminum main rear axle supports with coated alu eccenters; more rigid, better rear axle support for a very true running rear shaft, easy belt-tensioning, easy access for maintenance. With the eccenters you can choose 3 positions for rear- belt tensioning. By removing the eccenter on one side the rear shaft with pulley and belt can be accessed very easily. Main rear supports are machined maximum to reduced weight, but retain rigidness at the same time. Pins are pre-pressed into the bottom of the brackets which then seat into the positioning holes in the chassis. Precise and secure.

Suspension brackets

anodized, cnc machined aluminium suspension brackets to hold lower rear pivot pins, front and rear brackets

Carbon fibre parts

4mm carbon fibre suspension- brackets and rear shocktower. Rear shocktower features 4 position for shock-angle.

Fasteners / manual / set

High quality steel allen type screws throughout the car.

See the download section for the 966 pdf manual.

Release between mid/end february.

Team Serpent